ZTT has successfully commissioned the Yancheng Dafeng Port Solar-Hydrogen-Storage Integrated Energy Project, the first in Jiangsu Province to deeply integrate solar photovoltaic generation, local peak-shaving storage and green hydrogen production.

Leveraging the strategic location of Dafeng Industrial Zone’s “Green Hydrogen Production, Storage, Transport and Utilization Economic Belt,” the project adopts an off-grid solar direct supply plus multi-type energy storage coupled model controlled by ZTT’s self-developed smart microgrid system, this enables 100% renewable hydrogen production — a breakthrough in zero-carbon energy solutions.

Five Core Systems

Energy Supply & Storage – A 3MW rooftop distributed PV system is paired with a 1MW/2MWh lithium iron phosphate storage unit. An advanced Energy Management System (EMS) smooths generation fluctuations and optimizes local load peak-shaving.

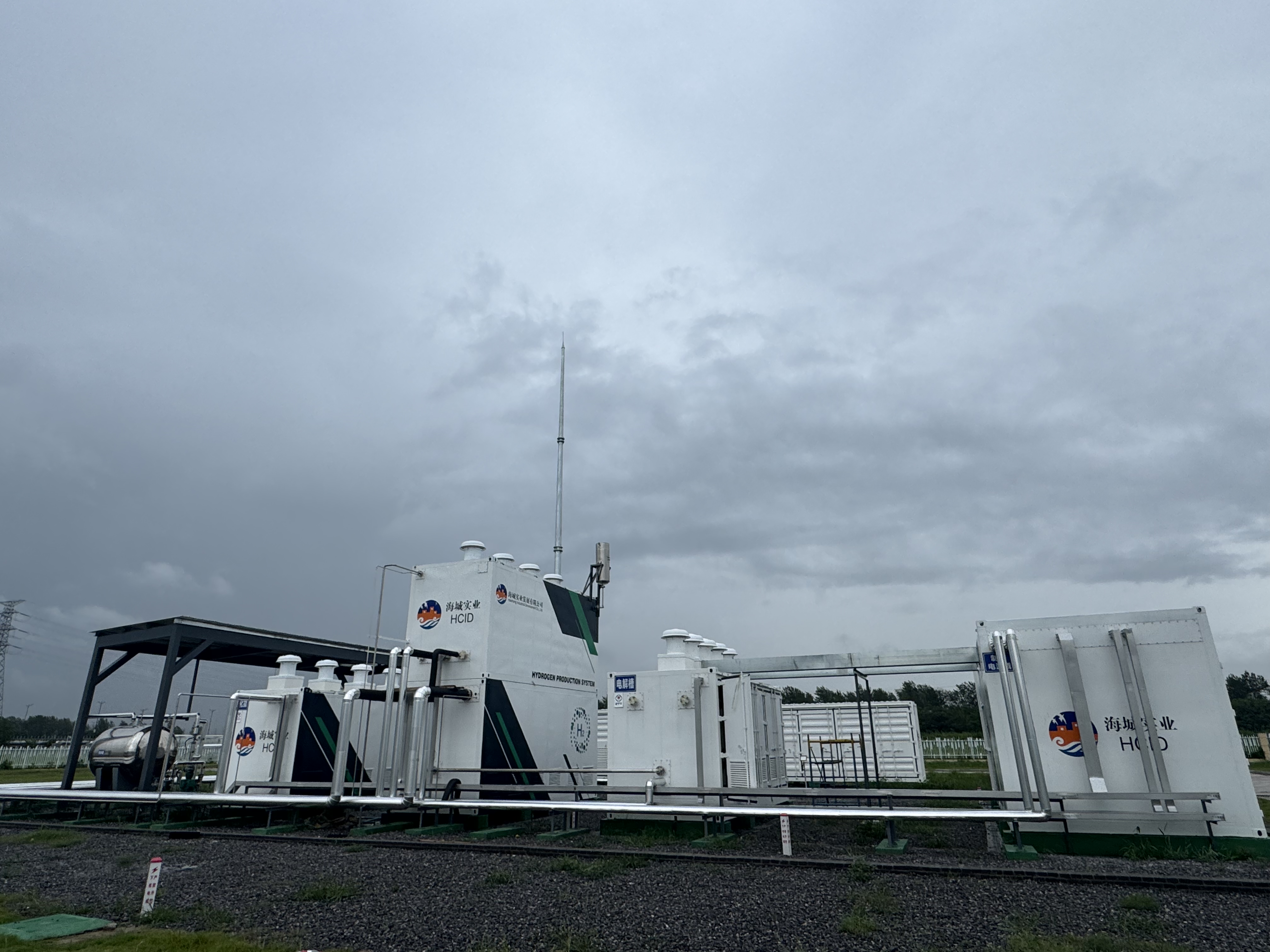

Hydrogen Production – The 400Nm³/h alkaline electrolyzer produces 46.8 tons of hydrogen annually, purified to 99.999% for industrial and transport use. Modular containerized design integrates purification, compression, and storage for rapid deployment.

Hydrogen Refueling – The refueling station has a capacity of 500kg/day using dual-pressure compressors (20MPa & 45MPa) capable of servicing heavy trucks, buses, and light-duty vehicles.

Off-Grid Control System – The proprietary microgrid platform co-ordinates across multiple time scales for generation, grid, load and storage, enabling real-time monitoring, optimized dispatch, and rapid response. Data is automatically aggregated, analyzed, and reported to maximize PV-storage-hydrogen generation efficiency.

Safety & Digitalization – This is achieved by continuous hydrogen leak detection and a digital twin system enable predictive maintenance, cutting fault response time by 30%.

Innovations and Impact

The project pioneers:

Independent microgrid hydrogen production, replacing traditional grid-connected models for a fully decarbonized process.

Civil works completed in 2.5 months, equipment installation and piping in 2 months, and commissioning in just 1.5 months

Enhanced electrolyzer performance optimized for fluctuating PV supply, achieving industry-leading efficiency.

The “PV-Hydrogen-Storage” industrial synergy platform integrating hydrogen equipment manufacturing, storage and transport and fuel cell technologies — creating a replicable blueprint for off-grid hydrogen production.

As a key hub in the Yangtze River Delta Hydrogen Corridor, the project will serve as a demonstration for deep decarbonization in industry, advancing China’s clean energy transition and hydrogen economy.